Machinery and complete lines

Cabbage shredder

This machine is made of ČSN 17 240 (DIN 1.4301) class stainless steel and meets all hygiene requirements under Decree 38/2001 Coll., including the carrier plate, which is also made of DIN 1.4301 stainless steel. The blades are manufactured in-house using hardened stainless steel and are hardened to a specific level of hardness. The shredder head is connected to the frame using pivot pins that permit it to be rotated away, providing easy access to remove the blades.

Model Height | KZ 600 / KZ 800 1250 / 1400 mm |

Width | 1000 / 1200 mm |

Length | 900 / 1100 mm |

Total power | 1.5 / 2.2 kW |

Output | 6 / 8 t/h |

Complete lines

We deliver complete technical assemblies based on a project or a special design. We recently delivered a poppy seed processing line with big-bag stations, screw conveyors, weighing hoppers, boilers, belt conveyors and filling screw conveyors with bag scales.

Another delivery was a sugar repacking line, which consists of a platform, a sugar hopper and sugar lump crushers, and we manufactured a root vegetable processing line. This line includes a washer, a screw conveyor, thermal steam peeler, brush scrapers and inspection conveyor.

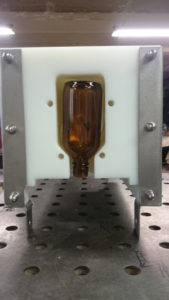

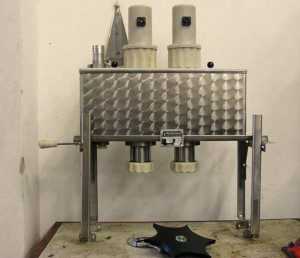

Plastic turners

Inverters are used to rotate glass and aluminium cans 180° before or after rinsing. We manufacture inverters from metal and plastic. Plastic inverters have one-third the installation dimensions, and may be fitted with rinse nozzles or a compressed air ports. Inverters are installed directly on a plate conveyor before the can or bottle enters the filler.

Technical details

Height : 2100 mm

Width : 1300 mm

Length : 4000 mm

Weight : 890 kg

Power rating : 5.2 kW

Output : 10 t / h

Application :

The machine is designed to strip leaves from cabbage heads. It is manufactured from ČSN 17 240 (DIN 1.4301) stainless steel and meets all requirements under Decree 38/2001 Coll. Leaf stripping involves rollers that are partially rubber coated. The leaf stripper is driven by a TOS ZNOJMO variable gearbox and is equipped with a radial fan that aids in the leaf stripping process. The machinery includes a 500 mm wide and 4000 mm long transfer conveyor.

Steam peeler

The machine uses rooted vegetables for steam-thermic peeling. The surface layers can be eroded and peeled using steam. The machine is run by the LOGO SIEMENS programmable unit. The machine is made of stainless steel 17 240 and 11 353 and meets the hygienic requirements set by the ČSN EN 1672-2 standard.

Technical information: | |

Height of the machine | 2550 mm |

Width of the machine | 1930 mm |

Length of the machine | 2170 mm |

Weight of the machine | 650 kg |

Steam supply | 0.8 MPa |

Input power of the machine | 1-3 t/h according to the materials |

The fillers produced by us are able to fill peas, cubed vegetables, cabbage, kale and even hard liquors.

We also perform general repairs to the PLAO fillers (pepper stew and sauces). We even included dry mixture bagging machines in the production program.

Washers

We manufacture stainless steel brush, air and pump washers. Washers feature low potable water and energy usage. Sealed bearings, packing systems and modular conveyor belts are all standard.

Blancher

This machine is used to cook and blanch cabbage, corn and peppers. It incorporates a robust auger with 3 clean outs, three automatic control valves, condensing pots and digital thermometers. Steam is supplied to the machine. Speed is controlled using variable frequency drives. Product temperature is controlled by 3 sensors which control the steam supply. The machine is made of 1.4301 class stainless steel and meets all hygiene requirements under Decree 38/2001 Coll.

Internal diameter | 400 mm |

Width | 830 mm |

Length | 5900 mm |

Weight | 1100 kg |

Steam supply | 0.1-0.3 MPa |

Output | 1-3 t/h depending on product |

Machines for the food processing industry is our principal manufacturing program. We have many years of rich experience within this industry. We make cabbage strippers, cabbage drillers, root cutters, screw blanchers, steam-thermic peelers, pickle batchers, preservation basket lifters, filler tables. We also made a meat presser for the meat industry sector and we make drums for cleaning products for the confections industry. In our company, we make one or two single-purpose machines according to customer’s request every year.

Coring machine

This machine is a dedicated cabbage corer. This machine is made of ČSN 17 240 (DIN 1.4301) class stainless steel and meets all hygiene requirements under Decree 38/2001 Coll. A pneumatic piston is used to press the cabbage against the cutting bit to remove the core. The cabbage is then dropped into a shredder.

The machine is equipped with hardened stainless steel cutting bits with a special shape to grinds up the removed core. It automatically adapts to head size and the required coring depth. Several of these machines are currently being operated by customers from Czech Republic, Slovakia, Poland and Belarus.

Height of the machine | 1960 mm |

Width of the machine | 850 mm |

Length of the machine | 850 mm |

| Weight of the machine | 125 kg |

Input power of the machine | 2.2 kW |

Pressure | 4-6 bar |

Power | 6t / h |

Air consuption | 1350 l / h |

We concentrate on production, repairs, adjustments of various machines and service lines, especially within the food processing industry. This industry requires machines and service lines made of stainless steel. It is primarily stainless steel made under DIN 1.4301. Considering the diversity of the machines used in the food processing industry, the customer may opt for any kind of material according to the needs and norms that the machine will need to meet. Consultation with the customer and potential counselling are also very important in ensuring the quality and effectiveness of the machine or service line. The food processing machines that we produce include:

- plastic turners for turning glass objects

- coring machine

- cabbage shredder

- brush, air or pump washers

- fillers

- steam peelers

- continuous cabbage leaf stripper

- blanchers

We supply directions for use and declaration of conformity with any new machine or service line.

We also have older machines and devices available that could be reconditioned and then supplied to a customer. Some machines are more expensive, which is why this option is much more acceptable for smaller companies.